Sweeping rollers – for any application and for all common front-mounted sweepers and self-collecting machines

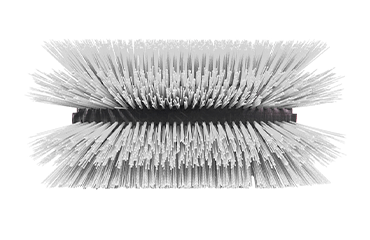

TWISTER - The scraper

>> Very smooth running

>> Effective transport

Great transporting effect due to the spiral arrangement of the bristles. The special rotating movement ensures smoother running and effective transport of the swept material to the suction mouth or collection container.

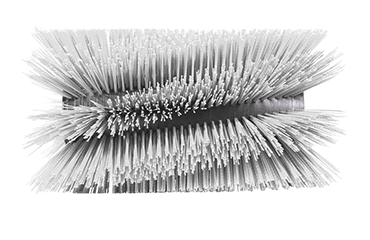

LIGHTNING - The effective

>> Universally applicable

>> High bristle density

Great transporting effect and high spinning effect. For any kind of soiling, from respirable dust to building site rubble.

GRIZZLY - The powerful

>>A mixture of crimped wire and plastic bristles

A mix of corrugated wire and plastic bristles loosens stubborn and encrusted dirt such as stuck clay. Ideally suited for building site cleaning.

THUNDER - The universal

>> Universally applicable

>> High bristle density

Effective and thorough cleaning of all kinds of dirt, from fine dust to construction site cleaning.

ALBATROS - The enduring one

>> Long service life

>> Low wear

High-performance nylon bristles ensure long service life.

Why is the placement and the mix of bristles so important?

Any sweeping roller is only as good as its bristles. Sweeping efficiency and service life are influenced by the bristle arrangement, the material mixture, as well as by the bristle strength and density. Premium quality raw materials are the basis for the quality and efficiency of our sweeping rollers. To ensure optimum cleaning efficiency, we adapt all components to each machine type and each application.

Deutsch

Deutsch

English

English

Suomi

Suomi

France

France

Ungarisch

Ungarisch

Niederländisch

Niederländisch

Italienisch

Italienisch